Health debate: Sugar beet vs sugar cane—is one better?

The Importance of Sugar Beet Vs Sugar Cane: a Closer Check Out Their Manufacturing Processes and Applications

The significance of sugar beet and sugar cane expands past their role as resources of sucrose. Each crop features distinct making procedures that affect their applications across various markets. While sugar beet supports not just food manufacturing but additionally biofuels and plant foods, sugar cane mainly offers the food sector with important results. Recognizing these distinctions discloses just how each crop forms agricultural economies and market techniques around the world, triggering further exploration into their one-of-a-kind contributions.

Summary of Sugar Beet and Sugar Cane

Sugar beet and sugar cane are 2 primary resources of sucrose, each with distinct attributes and cultivation methods. Sugar beet, a root vegetable, flourishes in pleasant climates - Sugar beet vs sugar cane. It is grown mostly in the Northern Hemisphere and requires well-drained soil. The plant typically grows to a height of concerning 18 inches, with a white, fleshy origin containing about 15-20% sucrose. On the other hand, sugar cane is a tropical turf that prospers in cozy, damp conditions. It can get to elevations of approximately 12 feet and includes tall, jointed stems that shop sucrose concentrations ranging from 10-15%. The cultivation of sugar cane is labor-intensive and typically includes hands-on harvesting. Both crops act as necessary farming commodities, offering raw materials for sugar manufacturing and various spin-offs. Their growing methods significantly affect local economies and global sugar markets, making them indispensable to the farming landscape

Collecting Strategies for Sugar Beet and Sugar Cane

Harvesting strategies for sugar beet and sugar cane differ markedly as a result of the unique characteristics of each plant. Sugar beet collecting commonly employs specialized machinery referred to as beet harvesters, which efficiently root out the beetroots from the soil while reducing damage. These devices make use of a collection of blades to reduce the tops and raise the roots, ensuring that the beetroots continue to be undamaged for processing.In contrast, sugar cane harvesting frequently includes two main approaches: manual cutting and mechanical harvesting. Hands-on harvesting, still prevalent in some areas, calls for employees to cut the cane stalks by hand using machetes. This approach enables selective harvesting but is labor-intensive. Mechanical harvesters have actually gained popularity, utilizing rotating blades to reduce and collect the stalks quickly. Both methods aim to optimize return and top quality, with mechanical harvesting progressively adopted to meet climbing production needs efficiently.

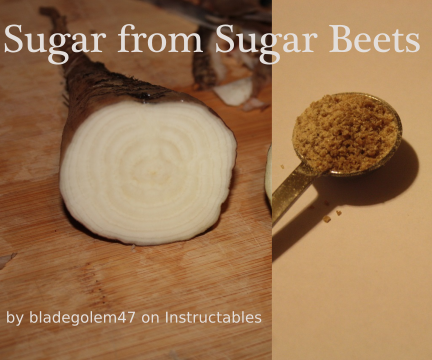

Handling Approaches for Sugar Beet

After being harvested, sugar beetroots go through a series of handling actions to extract sucrose efficiently. The very first step includes washing the beets to eliminate soil and contaminations. Next off, the beets are cut into slim strips called cossettes, which boosts the area for extraction. These cossettes are after that subjected to hot water extraction in a diffusion procedure, allowing sucrose to liquify right into the water.Following extraction, the juice contains pollutants and is made clear making use of lime and warmth to precipitate solids. The clarified juice is then concentrated with evaporation, eliminating excess water and boosting sugar focus. To crystallize the sucrose, the concentrated juice goes through additional evaporation and cooling, developing sugar crystals. Ultimately, these crystals are separated from the remaining syrup through centrifugation, dried, and packaged for circulation. This method ensures a high yield of sucrose while maintaining the high quality of the final product.

Processing Approaches for Sugar Cane

Handling sugar cane includes a series of steps made to draw out sucrose properly. The procedure begins with harvesting, where mature sugar cane is cut and delivered to refining facilities. Once at the mill, the cane goes through washing to get rid of impurities. The following step is squashing, where mechanical rollers essence juice from the fibrous stalks.This juice is then clarified using heat and lime to eliminate put on hold solids and impurities. Following information, the juice is vaporized to concentrate the sugar content, leading to a thick syrup. The syrup undergoes formation, where sugar crystals form as the syrup cools. These crystals are separated from the staying molasses via centrifugation.Finally, the sugar is dried and packaged for circulation. This detailed handling approach guarantees that sugar cane yields a premium item, ideal for numerous culinary and industrial applications, while optimizing the extraction of sucrose from the raw material.

Nutritional Differences Between Sugar Beet and Sugar Cane

The contrast in between sugar beet and sugar cane extends past their processing methods to incorporate considerable nutritional differences. Sugar beet includes not just sucrose but also an array of nutrients, consisting of vitamin C, potassium, and magnesium. These nutrients add to its possible health advantages, such as sustaining immune feature and keeping electrolyte equilibrium. In comparison, sugar cane generally offers sucrose from this source with marginal degrees of crucial nutrients.Additionally, sugar beet has a higher fiber material, which can assist in digestion and advertise satiety. The visibility of antioxidants in sugar beet might additionally supply protective impacts against oxidative anxiety, a factor connected to numerous chronic diseases. While both resources are mostly used for sugar production, the dietary profiles recommend that sugar beet might provide extra health and wellness advantages contrasted to sugar cane. This difference is critical for customers seeking greater than simply sweeteners in their diet plans.

Applications of Sugar Beet in Various Industries

A selection of industries take advantage of sugar beet for its versatile applications past sugar production. In the food industry, sugar beet works as a key active ingredient in creating different refined foods, including sweets and baked items, due to its all-natural sweetness. In addition, the pulp obtained from sugar beet is made use of as pet feed, offering a nutrient-rich resource for livestock.In the biofuel field, sugar beet is significantly recognized for its possibility in producing bioethanol, adding to renewable resource options. The farming market take advantage of sugar beet's results, which can be utilized as natural fertilizers, improving dirt health and fertility.Furthermore, sugar beet extracts are utilized in pharmaceuticals and cosmetics, where they operate as all-natural sweeteners and humectants. These varied applications highlight sugar beet's function as an important resource in boosting sustainability and development throughout numerous markets, strengthening its importance in modern-day production practices.

Applications of Sugar Cane in Different Industries

Regularly Asked Questions

What Environmental Effects Are Connected With Sugar Beet and Sugar Cane Manufacturing?

The ecological effects of sugar beet and sugar cane manufacturing consist of dirt degradation, water use, pesticide application, and habitat interruption. These elements add to environmental imbalances, elevating concerns regarding sustainability in farming methods related to both crops.

How Do Sugar Beet and Sugar Cane Contrast in Terms of Economic Practicality?

The economic feasibility of sugar beet and sugar cane differs based upon elements like geographic location, production prices, and market need - Sugar beet vs sugar cane. Both crops offer one-of-a-kind advantages, affecting farmers' decisions relating to cultivation and financial investment in different areas

What Are the Key Regions for Sugar Beet and Sugar Cane Cultivation?

How Does Environment Influence the Development of Sugar Beet and Sugar Cane?

Environment greatly influences the development of sugar beet and sugar cane. Sugar beetroots prosper in cooler temperatures, while sugar cane calls for warm, tropical conditions. Sugar beet vs sugar cane. Both plants depend on ample rains and sunshine for optimal advancement and yield

Exist Any Kind Of Substantial Health And Wellness Concerns Connected To Consuming Sugar From These Resources?

Health and wellness worries relevant to sugar usage include weight original site problems, diabetes mellitus, and cardiovascular disease. Both sugar beet and sugar cane-derived sugars can add to these problems, specifically when consumed in excessive amounts, despite their resource.